Fisher Price presents My First Moped

by David Couzens

Added: • Updated:

BUILD DESCRIPTION

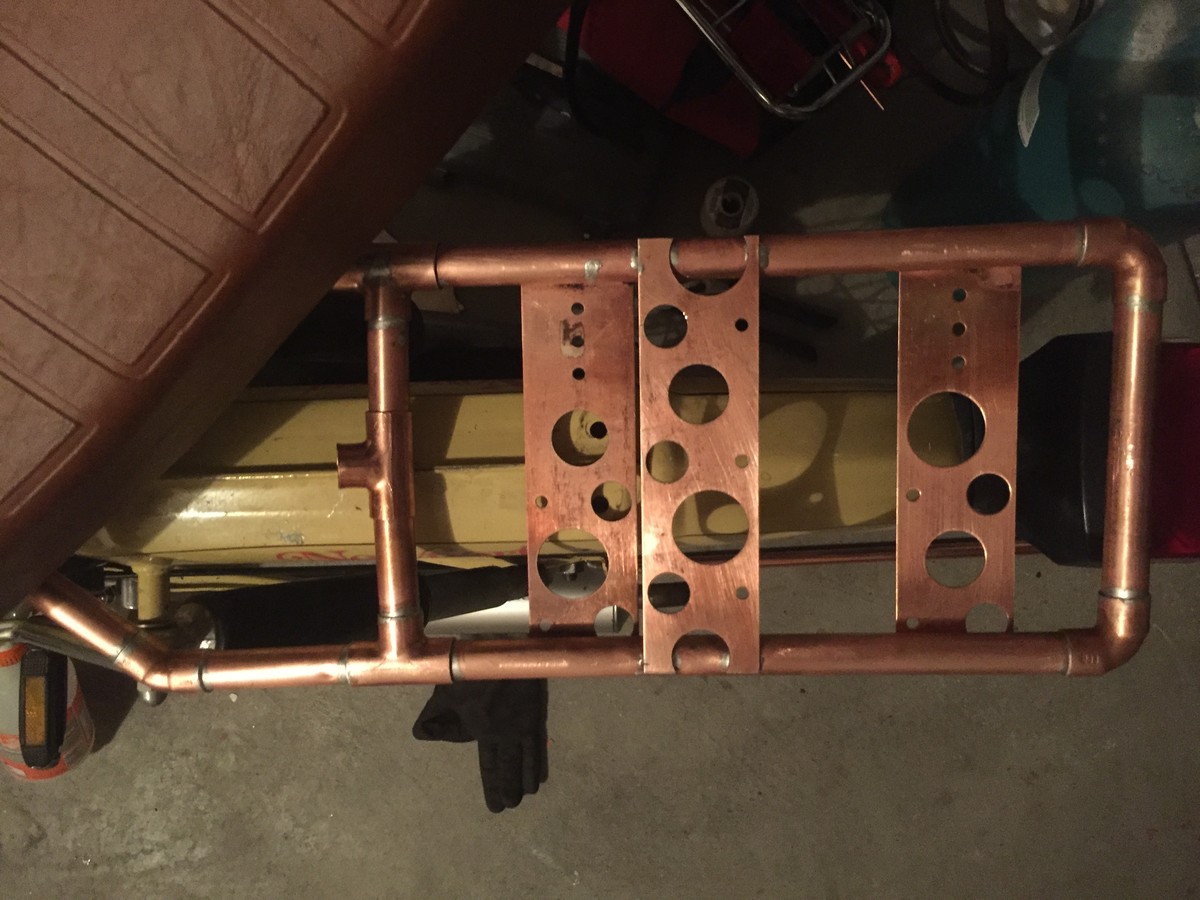

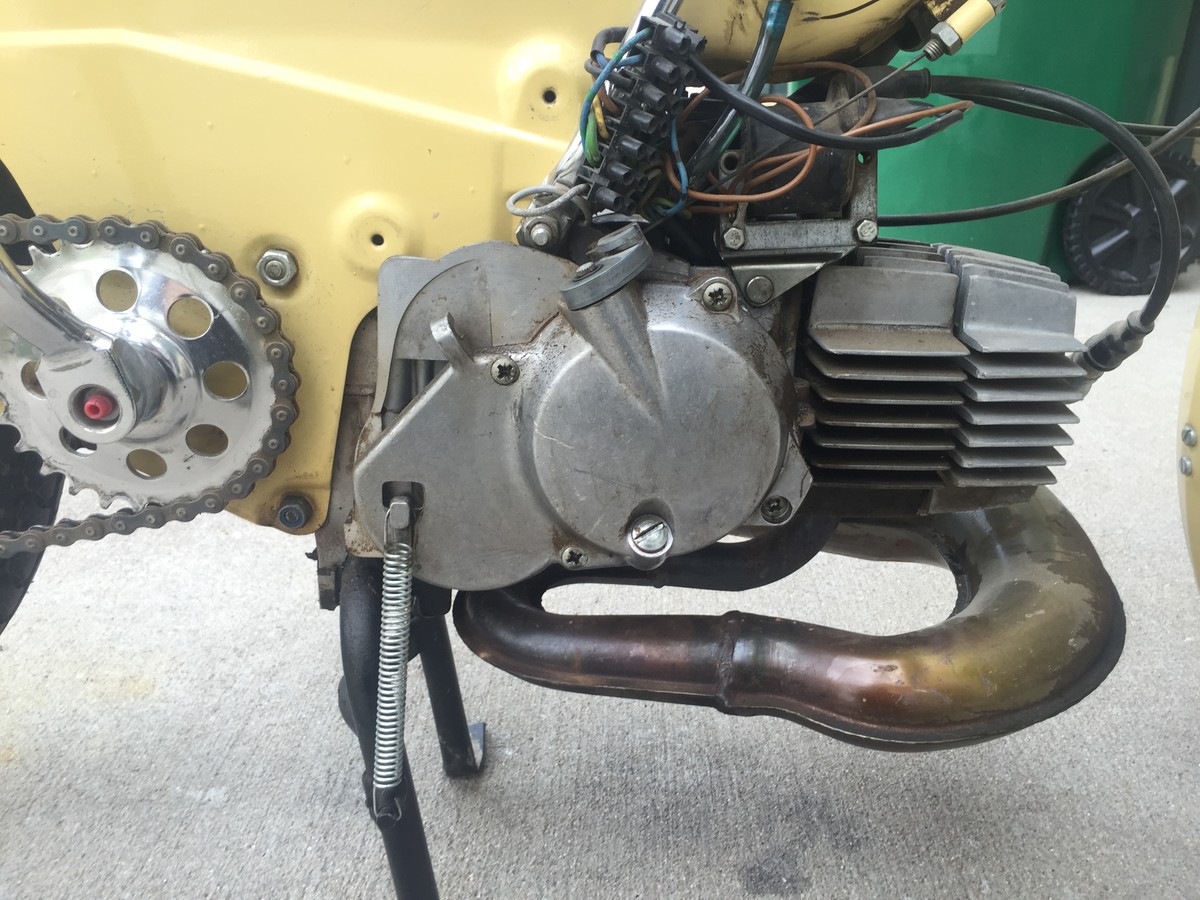

New to mopeds - just like the classic look tho will probably keep the pipe it has on it already. Current Pictures show the bike as is, how i bought it. Will update as I make changes. 10/7/15 - Switched out old seat for new long brown seat. Put on side covers. Replaced VDO speedo cable but it still doesn't work. Didn't have time to really investigate. 10/12/15 - Replaced the rear inner tube after getting a flat. Cleaned and lubed both chains. Swapped out gas cap for one with a lock. Cleaned out carb with sea foam - lots of smoke! Picked up a Kryptonite chain and fixed the speedo - top speed confirmed w/ GPS at 30.5 mph. 10/26/15 - • In order to mount the new longer seat AND keep the book rack, I had to fab up the copper bracketing. • The saddle bags are surplus German Army medic bags I order online – added grommets in the back to mount them. • I have also added a mirror so I can look back and see the road rage developing in drivers faces that are stuck behind me. • Replaced transmission fluid • Rebuilt the carburetor and cleaned the engine casing tho I’m still going to have to replace some internal gaskets because I noticed it was dripping a little bit of transmission fluid. 11/12/2015 • Added support to saddlebag to act as bracing. Used zip ties instead of just random wire laying around. • I thought i had a transmission leak but I think it was just the fill bolt leaking. Switched out the existing gasket for a rubber o-ring and it seems to be holding. Will keep an eye on it to see if the engine heats up the o-ring too much. • I have some air leaks I need to hunt down and fix. Need to make my own leak down test rig. Until I am able to fix them there is no point in trying to tune it further. 12/10/15 • Picked up Puch DMP 50cc cylinder kit, using the same head as before.(Spacing notes below in next edit) • Replaced 14mm Bing with 15mm bing clone. • Have ordered a 2.17 atomizer and 70s range of jets. • "FPP-MFM" starts up cold on first kick with barely a tap - however once its warm it idles like crap and dies. It will start up again but not as easily. I am led to believe this may be a bad condenser and also combined with air leaks. Next project is to fix leaks, clean points and make sure timing is right. If issues still persist, install external condenser. 12/23/15 • Had issues with getting leaks sealed - went and stripped all the engine studs along with the exhaust studs. Guess I had my torque wrench set too high. • Ordered some M6 threaded rod from Grainger and cut new pieces to size. • Put engine back together, but only way to have the right spacing is to use a 1mm base gasket and two .6mm head gaskets I had. Going to switch to 1.6mm base gasket and one head gasket.(on order from treats.) • In the mean time I haven't been able to get my base, the two head gaskets, or my intake gaskets to seal. It's quite irritating. I have some copper gasket paste that I attempted to use last go around but it left such a mess I don't really want to use it especially if I have a new base gasket coming. • I did the solder trick to find out the squish band thickness, came in at .7mm • I've been told I need to swap out the throttle slide from the 15mm bing clone with the 14mm bing slide as the clone one has an extra hole and won't idle correctly. 12/28/15 • Apparently I need to make sure that the piston will clear the head with just the base gasket and not get there by using a head gasket. That's what I've been told anyway. I'll try sandwiching some gaskets around the metal spacer I have and see what happens. • My current stock head seems to be a bit jacked/knicked along the bottom and I suspect is a cause of the trouble I've had getting a seal there. Ordered a new hi compression head with old style fins. • Tapped threads into the decomp hole on my cylinder. I may have screwed myself by going with M7, can't seem to find an M7 set screw anywhere - d'oh! • Ordered M7 rod and loctite from Grainger, will make my own set screw. • Have the trail tech temp sensor and mounting bracket on order with a 24" extension cord. • Should receive 17 Teeth front gear today in mail. Gearing will be 17x45 • Also have ordered the Proma Circuit pipe 12/29/15 • Can't believe it, but I found some M7 hex bolts at Ace Hardware, they only had like 3 different sizes. I cut the head off, sawed a slit for a flat head screw driver and plugged the decomp hole with it and some loctite. • As of right now, I've decided to try sandwiching the 1mm metal plate with two gaskets for enough space for the piston to clear the head. • I have very minimal air leaking from the base gasket, and some from the air intake. I do suspect its leaking within the e50 case bearing seals - it seems to drop too quickly for the small amount of bubbles coming from the gaskets. • The screw to set the points opening wasn't budging for me and I didn't want to strip it, it seemed to open between 14 and 15 thousands of an inch. I would like it to be between 16 and 17, for now its close enough. • I marked up TDC, 14 and 17 degrees BTDC on the fly wheel, I pushed the stator as far as I could, but I haven't check what its firing at yet while running. I bought a timing light from HF but now I can't find it. Won't have time to really look for it or even mess with it once I do until the weekend. • I have a goal of having everything how I want it(for now) by the 10th of January. Assuming treatland ships out my latest order(new head, temp gauge, pipe) sometime quickly after new years. I also need to replace front tire and shorten some of the cables. 12/31/15 • Ordered a stock crank off some dude from MA for $30 shipped, bearings and seals should be good. I didn't feel like having to rebuild my own crank, hoping I can just swap mine out easy enough • Found my timing light! Still haven't used it tho. • No way I'm gonna make my goal of the 10th, I won't get my treats package until the 6th...I'm going to make it more realistic and give myself til the end of January • Ultimately, I'd like to put on mag wheels, a chrome front fender, chrome side covers, chrome wire cover, chrome flywheel cover and swap out the handlebar for the low rise stemmed ones, but most of that can wait until treats next sale. 1/12/16 • Decided to keep original crank, and replace bearings and seals. Picked up new bearings and seals locally. Unfortunately I was misled to believe I needed the wrong seal size on the odd one. I reused the one on the other crank as it looked better. For Future reference, the e50 requires (2) 17x40x7 oil seals, and (1) 22x40x7 oil seal. (3) 6203 C3 bearings and (1) 6203 NR bearing. • Cleaned and washed e50 case • Used The Right Stuff gasket sealant • Swapped all the clutch cover screws and engine case screws to allen head screws. Much nicer! I didn't go with the SS ones from treats, I just picked up some black steel ones from Home Depot. (8) M6x30mm (5) M6x50mm and (4) M6x20mm • Was able to get the points screw unstuck, so once I have it all ready to time again, I can set that correctly at 16/17 thousands of an inch. • Did another leak down test..still can't seem to get it to seal. Argh! 1/13/16 • Hazzah! I figured out my actual leakdown tester was leaking! I need to make one with a valve shutoff. I think I still have a tiny leak..somewhere..but its really tiny and I ain't worried about it for now. • Got the engine mounted back onto frame, ran the brake and throttle cable under the cable cover as well. I may end up doing something different with all the cables running down because it looks like crap by whomever did it before me. • I switched out the throttle slide from my OG bing carb into the new bing clone. • Put on the 17 tooth front gear • Set point gap at 17, I think it have it timed correctly at like 15 degree before TDC. That'll have to wait for confirmation 1/25/16 • I screwed up on a brake light wire when I was messing with the cable run. front brake lights up but not rear. Its on the list to fix but at the bottom • It starts up but won't idle and for sure won't run with any load on it...I'm not really sure what the issue is - sometimes it will act/sound normally and throttle up, but not under load and most of the time I have to have the throttle open for it to even weakly try and idle. • I'm pretty sure I have the point gap and timing set correctly...but I need to confirm this still. • I also need to do a compression test • For some dumb reason I went and bought a "lightly used" airsal kit and hi compression head from someone on MA - I should probably get the puch running normally before installing this - but if I can't seem to get it running I'll swap it on. I think I am paranoid that I screwed up the piston/rings while messing with the rebuild because I had some threaded marks/grooves on the piston somehow. I tried to file them down as well as I could but not confident I'm getting any compression now. 1/26/16 • I'm not getting any spark now for some reason - getting super annoyed with this! • I need to take a day off from work and figure this crap out. • • •

BUILD DETAILS

MOPED

1977 Puch Newportengine

- Engine: Puch E50

- Cylinder: Puch 50cc Airsal

- Crank: Stock Crankshaft

carburetion

- Carb: Bing 15mm Clone

- Main: 78

exhaust

- Pipe: Puch Proma Circuit

electrical

- Ignition: Puch Stock Points

transmission

- Clutch: Puch E50 Stock 2-Shoe

2 LIKES

SHARE

1 COMMENTS

Sign in or Create an Account to post a comment.

Tyler Brekke:

Hey David, can you reupload the photos? I broke some of them... sorry!